- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

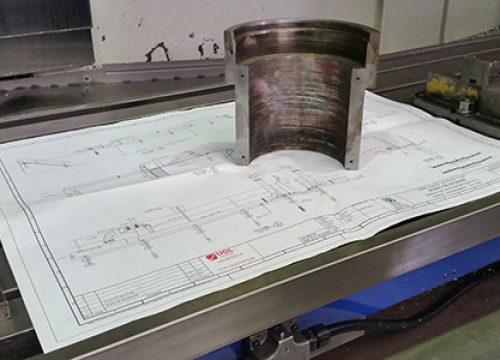

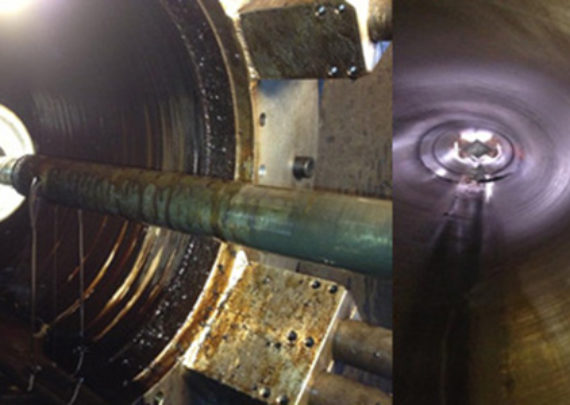

The customer required the honing of a varying range of both internal diameters and lengths

(450mm diam x 3.8m and 260mm diam x 4.2m) for non-destructive testing (NDT) purposes.

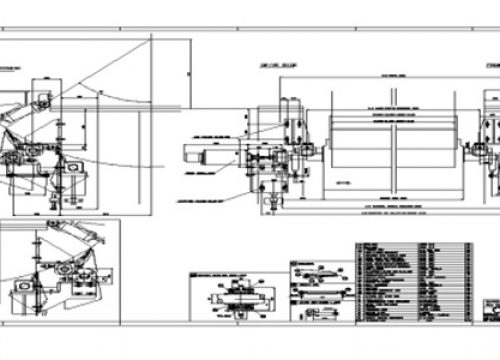

The requirements of the task included : portability, light-weight construction to enable safe manual handling and it had to be able to be mounted on differing diameter shafts.

DMM eng Innovative Solution:

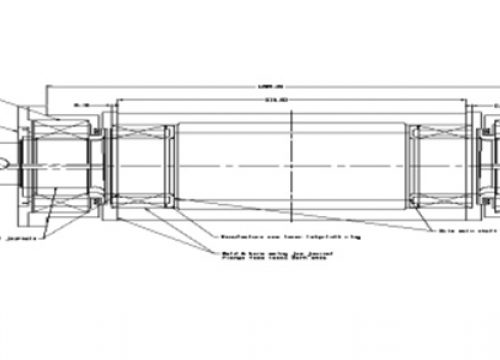

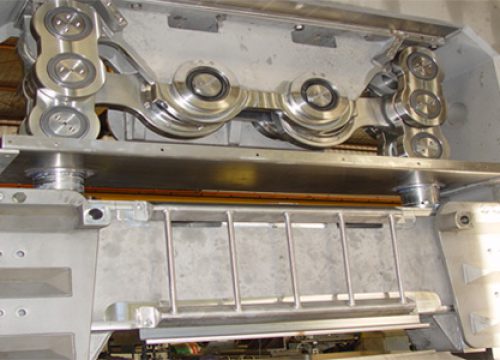

DMM eng designed, drafted and manufactured a hone constructed with chrome molly tubing, plastic, nylon and aluminum, incorporating a dual hydraulic drive unit with variable speed control and auto reverse. The honing unit was fully tested in the work shop prior to in-situ honing.

Service Delivered :

The DMM eng team of four staff, working two tradesmen per ten hour shift, over a seven day scope delivered what was promised.

Customer Benefit:

The task was completed locally, on schedule and met the specification accuracy as scoped. This enabled the customer to implement NDT and the inspection of the equipment to determine the need for repair work, as required. This delivered a significant saving in time and potential destructive testing costs.

Download PDF