- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

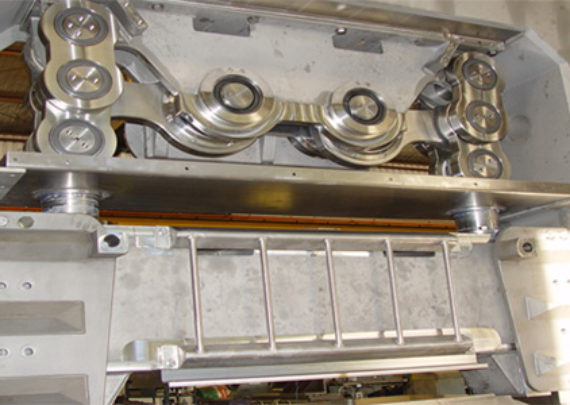

The design and fabrication of a corrosion resistant, stainless steel, fish fillet press was thought to be impossible. The customer was operating a 20 year old press which was fundamentally flawed and out dated, being hydraulically driven, made from carbon steel, and required frequent greasing, which in a food environment, is difficult to safely maintain.

DMM eng Innovative Solution:

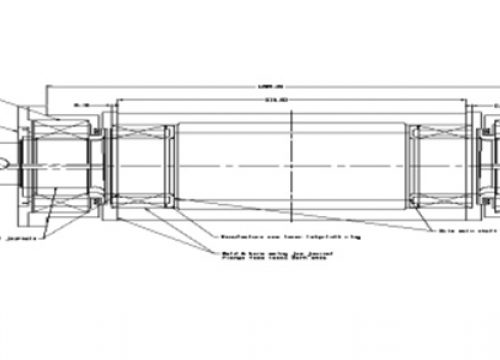

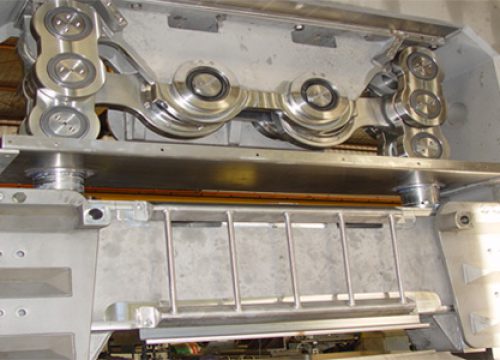

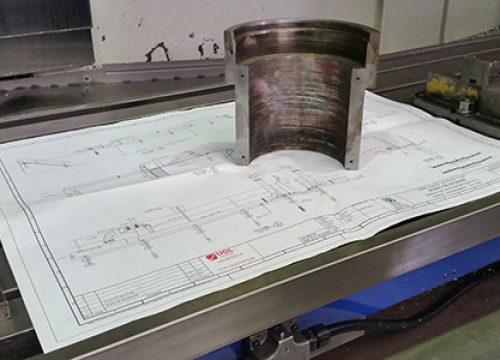

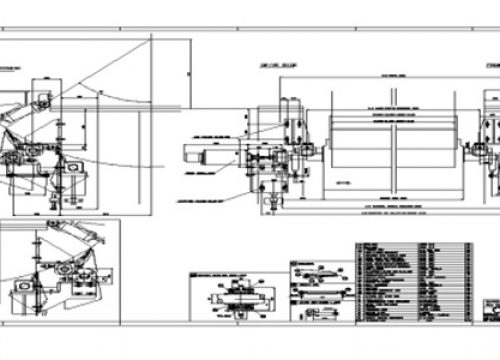

The DMM eng team worked collaboratively with electrical and mechanical engineering teams in the design, fabrication, machining, assembly and

commissioning of the new press and overcame all the conventional challenges of wear and binding problems normally incurred with stainless steel in this type of equipment. The design team placed a high degree of importance on operator safety, incorporating a comprehensive risk management approach to engineering out any possible interaction between the machine and the operator.

Service Delivered :

The DMM eng team brought to the project skilled engineering expertise, exacting machining and fabrication skills and incorporated a number of practical design changes to assist in the manufacture of the press. The effective collaboration across the team of design, electrical, DMM eng and customer staff enabled the best possible outcome, including the design and manufacture of a trolley to maneuver and install the press into position, which presented unique challenges with height, existing plant & equipment constraints.

Customer Benefit:

A safe, fully functional, highly reliable, long service life fish meal press was put into 24 by 7 operation, on schedule and to budget.

The DMM eng team has demonstrated that it can deliver a one stop shop to design, fabricate, machine, assemble, deliver and commission purpose built plant and equipment. In addition, DMM eng provides follow up services to evaluated machine durability and reliability, and can develop recommendations to enhance machine availability to improve the customers’ bottom line.

Download PDF