- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

Repair a major crack failure in a boom in the shortest time frame and ensure the repair corrects the root cause of the cracking.

DMM eng Innovative Solution:

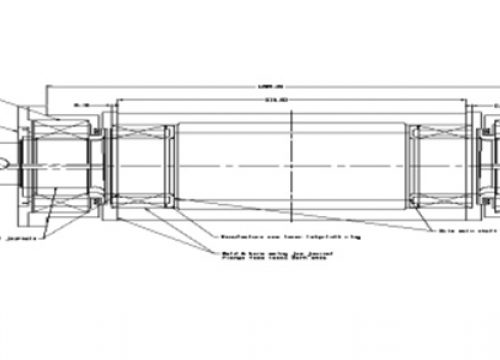

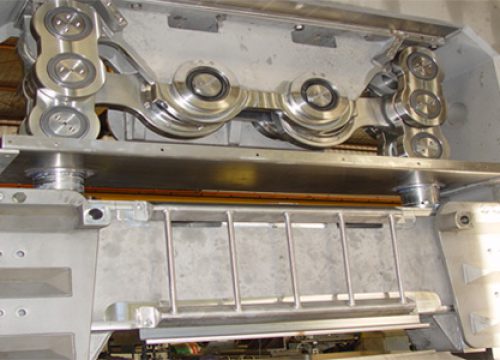

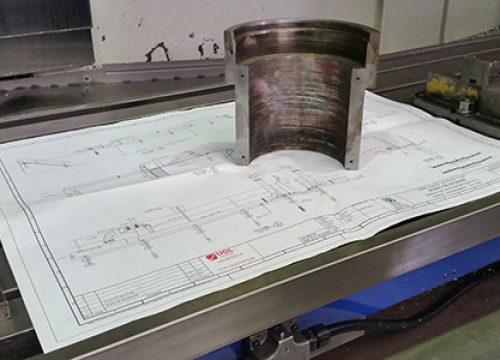

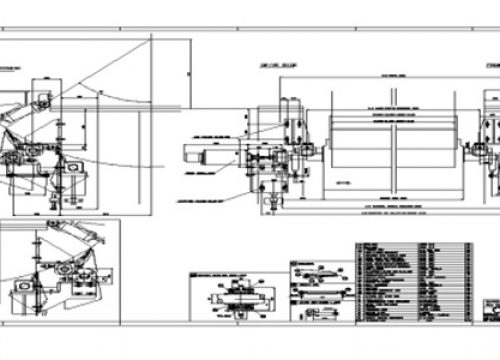

Detailed inspection of the crack propagation and operating load analysis were done to determine the best repair methodology. Significant field experience and sound engineering judgement was used to plan the repair process.

Service Delivered :

The DMM eng team was engaged to strip the boom from the machine while it was still on-site, and transport the boom to the DMM eng workshop. The damaged area was cut out, installation and welding of a new bush and accurate line boring completed the rebuild. The DMM eng team of two staff per shift worked two shifts over the weekend to meet the customer’s time frame. The boom was delivered back to site and re-attached.

Customer Benefit:

A permanent repair of the crack was achieved in a very short and ideal time frame over a weekend, with minimal need for the customer’s staff to support the work tasks, delivering the boom back into service in the shortest possible time.

Download a PDF